| Processing material | Silicon | Silicon carbide |

| Processing rod diameter | 3~8inches | 6~12inches |

| Processing rod length | 400mm | 300mm |

| Ovality | ±0.02mm | ±0.01mm |

| Conicity | ±0.05mm | ±0.015mm |

| Diameter accuracy | ±0.05mm | ±0.05mm |

|

Surface roughness |

Ra≤1.2μm | Ra≤1.2μm |

| OF Width Head-Tail Deviation | ±0.5mm | ±0.1mm |

| Crystal Orientation Precision | ±10' | ±10' |

| V-NOTCH Depth | 1.00~1.25mm | 1.00~1.25mm |

| V-NOTCH Angle | 89°~93° | 89°~93° |

| Equipment overall power | 21kW | 20kW |

| Equipment weigth | 5t | 4.5t |

| Equipment size | 3800*1620*2150 | 3620*1800*2000 |

Can accommodate processing of 4-8 inch crystals

Processing Length0-500mm

Mitsubishi control system

Equipped with automatic lubrication system

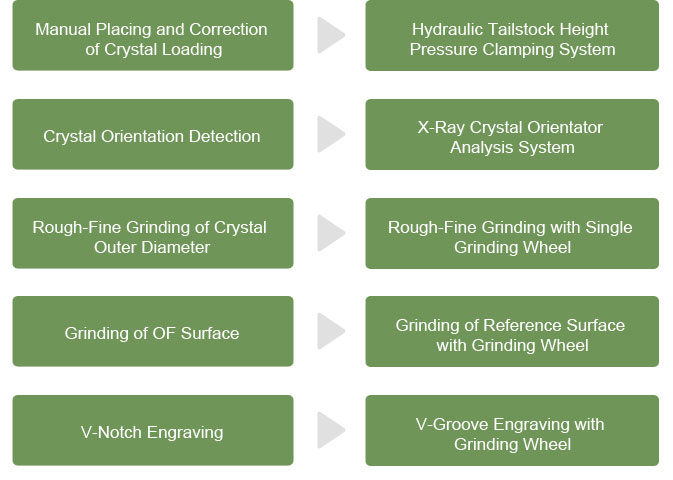

Outer Circle Grinding

Measurement of Crystal Orientation Angle

Grinding of OF Surface

V-Notch Engraving

Surface Smoothness Ra0.8-1.00

Eccentricity 0.02/500mm

Taper ±0.05/500mm

Radial Precision ±10'

Silicon

LT/LN

Silicon Carbide

Gallium arsenide/indium phosphide